|

|

|

|

FIBER OPTIC FUSION SPLICE PROTECTION SLEEVES |

Series VRA - RIBBON |

|

|

| |

Code: VRA-L-XX |

|

|

Fiber Optic Fusion Splice Protection Sleeves |

| Part No. |

L |

Lp |

D |

Dp |

d |

Stock |

| Series VRA8 |

Fiber size: 250 from 2 to 8 Ribbon fibers |

| VRA8-25-XX |

25 |

25 |

3,6x3,8 |

1,5x3 |

1x3 |

|

| VRA8-30-XX |

30 |

30 |

3,6x3,8 |

1,5x3 |

1x3 |

|

| VRA8-40-XX |

40 |

40 |

3,6x3,8 |

1,5x3 |

1x3 |

√ |

| Seria VRA12 |

Fiber size: 250 from 2 to 12 Ribbon fibers |

| VRA12-25-XX |

25 |

25 |

4,4x4,6 |

2x4 |

1x3,5 |

|

| VRA12-30-XX |

30 |

30 |

4,4x4,6 |

2x4 |

1x3,5 |

|

| VRA12-40-XX |

40 |

40 |

4,4x4,6 |

2x4 |

1x3,5 |

√ |

| ♦ Other size available on request. All dimensions in mm. |

|

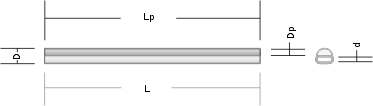

L - Length after recovery

Lp - Pin length (D type)

D - Outer diameter after recovery

Dp - Pin diameter (D type)

d - Hole diameter before recovery

XX - Color

|

√ - Stock

- Production - Production

|

|

| Available colors |

| 00 = clear √ |

01 = black

02 = brown

03 = red

04 = orange

05 = yellow

06 = green

|

07 = blue

08 = purple

09 = grey

10 = white

11 = pink

12 = turquoise

|

* Other color available on request.

The colored fiber optic fusion splice protection sleeves are utilized when there is a need for a quick identification of fibers in optical fibers’ splice box. The possibility of marking same-color pigtails in pre-organized optical fibers’ distribution frames is another advantage which can significantly accelerate installation works in client’s company. Moreover, the colored fiber optic fusion splice protection sleeves fully safeguard splice optical fibers, protect them from mechanical damage, pollution and atmospheric conditions, not causing additional losses of optical power.

The colored fiber optic fusion splice protection sleeves are utilized when there is a need for a quick identification of fibers in optical fibers’ splice box. The possibility of marking same-color pigtails in pre-organized optical fibers’ distribution frames is another advantage which can significantly accelerate installation works in client’s company. Moreover, the colored fiber optic fusion splice protection sleeves fully safeguard splice optical fibers, protect them from mechanical damage, pollution and atmospheric conditions, not causing additional losses of optical power.

|

| Product description |

VRA RIBBON series sleeves are applied in bar fiber-optic cables of the RIBBON type. They enable to secure up to twelve fibers in one sleeve. Excellent climatic and thermal properties make it ideal for use in closed as well as open spaces. The main goals during design phase were: full protection of the fiber optic splices and quickness of assembly. Initial shrinking of the sleeve was taken into account during the production process to reduce the gap between the tubes. This protects the internal tube and ceramic strengthening element from falling out. The final product is checked to meet the requirements set by the GR-1380-CORE standard of Telcordia Technologies Inc and ZN-96TPSA-006 standard of Polish Telecommunications. The sleeves we produce offer full protections the fiber optic splices. They do not cause additional insert losses, and they offer protection against mechanical damage, pollution and weather conditions.

VRA series is characterized by ability to secure up to 12 fibers in one shield and quickness of

assembly (120s). The sleeve consists of a D-shaped ceramic strengthening element

(dimensions 1.5x3mm up to 8 fibers, 2x4mm up to 12 fibers), a thin external tube and an internal

tube with a 1x3mm hole for up to 8fibers and 1x3,5 hole for up to 12 fibers.

Such a solution enables using those sleeves to protect bar fiber-optic cables with a 250um cover

The internal tube is made from special material EVA with good adhesion to many materials and

low solubility in water. It changes its consistency to semi-liquid in growth temperatures. It enables

to eliminate air bubbles through filling up the spaces between external tube, the Pin and fiber optic

cable. The Pin that stiffens the splice is made from ceramik 95% Al2O3 Helf Cylinder with heat

extensibility indicator identical to that of optic fiber. This prevents from longitudinal stresses on

the splice during heating process. Longitudinal stresses of the splice influence on growth a insert

loss and a reflection loss. In extreme cases they may cause breaking the connection, which makes

it necessary to repeat the splice procedure. External tube made from PEX, cross linked

polyethylene. The material guarantees sustainability and resistance to stretching and puncture. It

offers optimal air permeability, high gloss and smooth surface. It fulfills the requirements of Ul224

and MIL-I-23053 standards.

The standard sleeves are made in clear color. Other color available on request.

|

| Product properties |

- Outer diameter after recovery: 3,6x3,8 (up to 8 fibers); 4,4x4,6 (up to 12 fibers) mm +/- 0,2mm

- Hole diameter before recovery: 1x3 (up to 8 fibers), 1x3,5 (up to 12 fibers) mm

- Pin diameter (D type): 1,5x3 (up to 8 fibers), 2x4 (up to 12 fibers)mm ceramika 95% Al2O3 Helf Cylinder

- Minimum installation temperature: 170 °C

- Max installation time: 95 seconds

- Standard color: Clear

- Compliant norms: UL224, MIL-I-23053, GR-1380-CORE, ZN-96 TPSA-006

- RoHS compliant

- Packing: 50pcs packed to one zip-bag (other packing method available on request)

|

| How to order: |

VRA-40-00(50) - 50pcs packed to one zip-bag (Standard packing)

VRA-40-00(100) - 100pcs packed to one zip-bag

* Other packing method available on request.

|

|

|

|

|